Manufacturing and processing technologies

Press processing technology

We use our original high speed automatic press machines to produce high precision processed parts to meet the needs of our customers.

Using high-precision, multi-process pressing technology, we contribute to the compounding of functional materials and the reduction of man-hours for our customers.

3D processing, 3D trimming processing

We 3D-process an insulating sheet by 3D shaping technology, let alone a conventional way of pressing or folding.

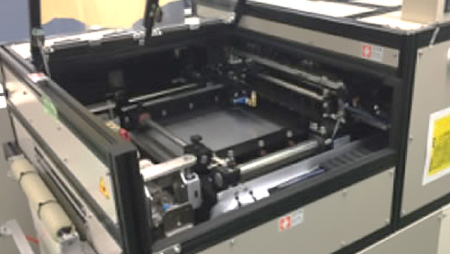

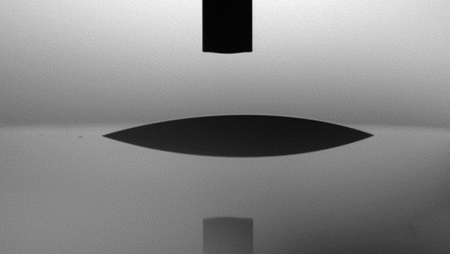

Laser processing technology

We are working on the development of new shapes that have never been processed before by non-contact processing with a laser machine. We have lasers available for resin and metal.

It is possible to respond speedily because it does not cost a mold.

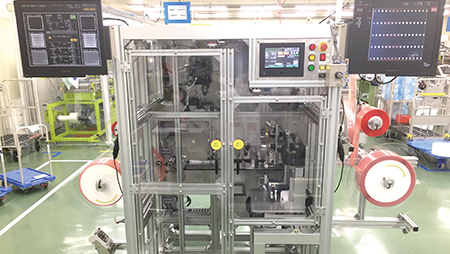

Flat surface bonding technology and Curved bonding technology

We have precision sheetfed laminating equipment in our clean room.

It is a device that automatically corrects the position and laminate in a natural state without stress.

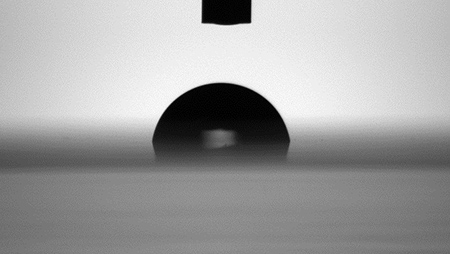

Surface modification technology

Image of resin material modification

This is a technology that imparts a new function to a material by applying a special treatment to its surface. By modifying the optical film, it is possible to improve the adhesion between the film and the adhesive material. Roll-to-roll treatment is also possible.

Clean processing technology

We have multiple clean rooms both in Japan and overseas, and can handle assembly and processing work that is considered difficult in a general environment.

We offer a range of environments up to class 1,000 (ISO 6), depending on the level of cleanliness you require.

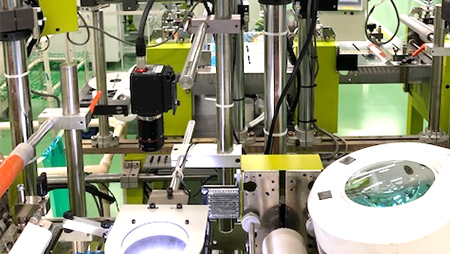

Assembly・ Module assembly

From prototypes to mass production, we can assemble and process products according to the customer's requirements. In addition, we have an assembly system in place to meet various requests for delivery and quality.

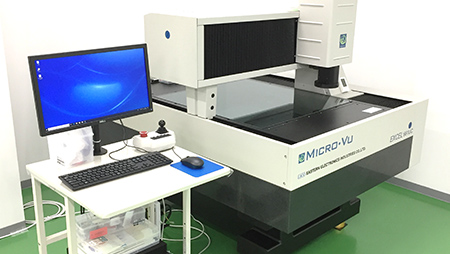

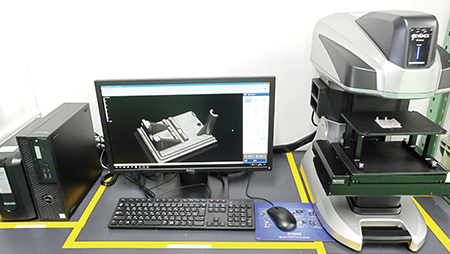

Visual inspection

Since dimensional accuracy is required to be equal to or greater than that of processed metal products, we are equipped with high-precision image measuring equipment to ensure the dimensional accuracy and appearance quality we have promised.

Evaluation equipment

In order to improve the quality and reliability of our products, we conduct measurements and tests on a daily basis.

We are working to improve product quality by evaluating products at the development and prototype stages, improving yields through analysis of defective products, and conducting reliability/durability tests to identify degradation factors or changes in characteristics and provide feedback.